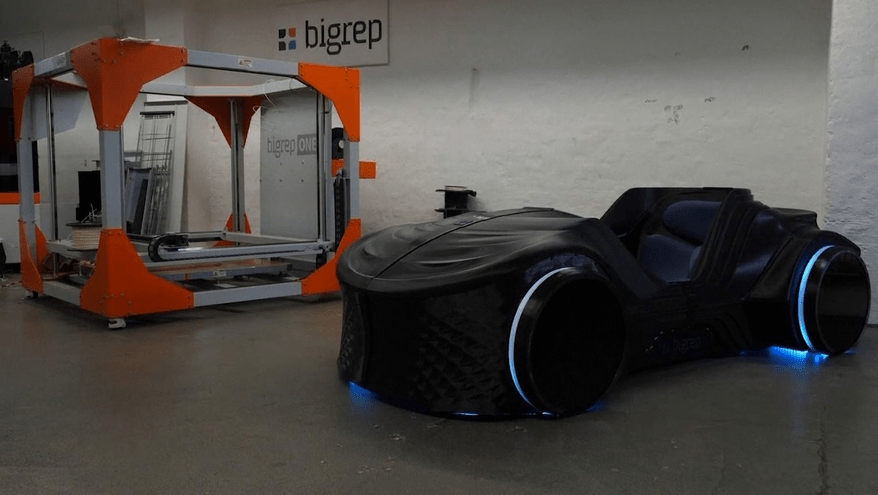

We begin our tour of the 3D printing industry this month with an additively manufactured concept car. Local 12 reports on LOCI, a fully 3D printed concept car developed by Berlin-based BigRep. Every component, down to the tires, of this batmobile-looking concept car, have been 3D printed. Indeed, even the largest part of the car, which “measures 1000 x 600 x 700 mm, was fully 3D printed in one piece.”

While LOCI is only a prototype for now, BigRep believes their concept car “can point to the future where vehicles are created in large 3D printing machines instead of standard factories.”

Traditional forms of car manufacture are time-consuming, and entire factories have to be set to create a new car. However, with the wonders of 3D printing, this entire process can be revolutionized.

As BigRep’s Chief Innovation Officer Daniel Buening explains: “the vehicle consists of only 14 3D printed parts. The development, from an idea to a finished project, took only 12 weeks.”

BigRep also envisions further instant personal vehicle customization when 3D printing becomes a vital part of the automobile manufacturing process. Buening elaborates: “tall people could order cars with slightly more head space in the cockpit and people with disabilities could ensure their cars were more suited to their needs. This also means you can design and produce faster. You can print the parts you need on-demand. You can also look at the sustainability aspect: moving spare parts around the world won’t be needed if you produce them locally in the factories instead of flying them across the world.”

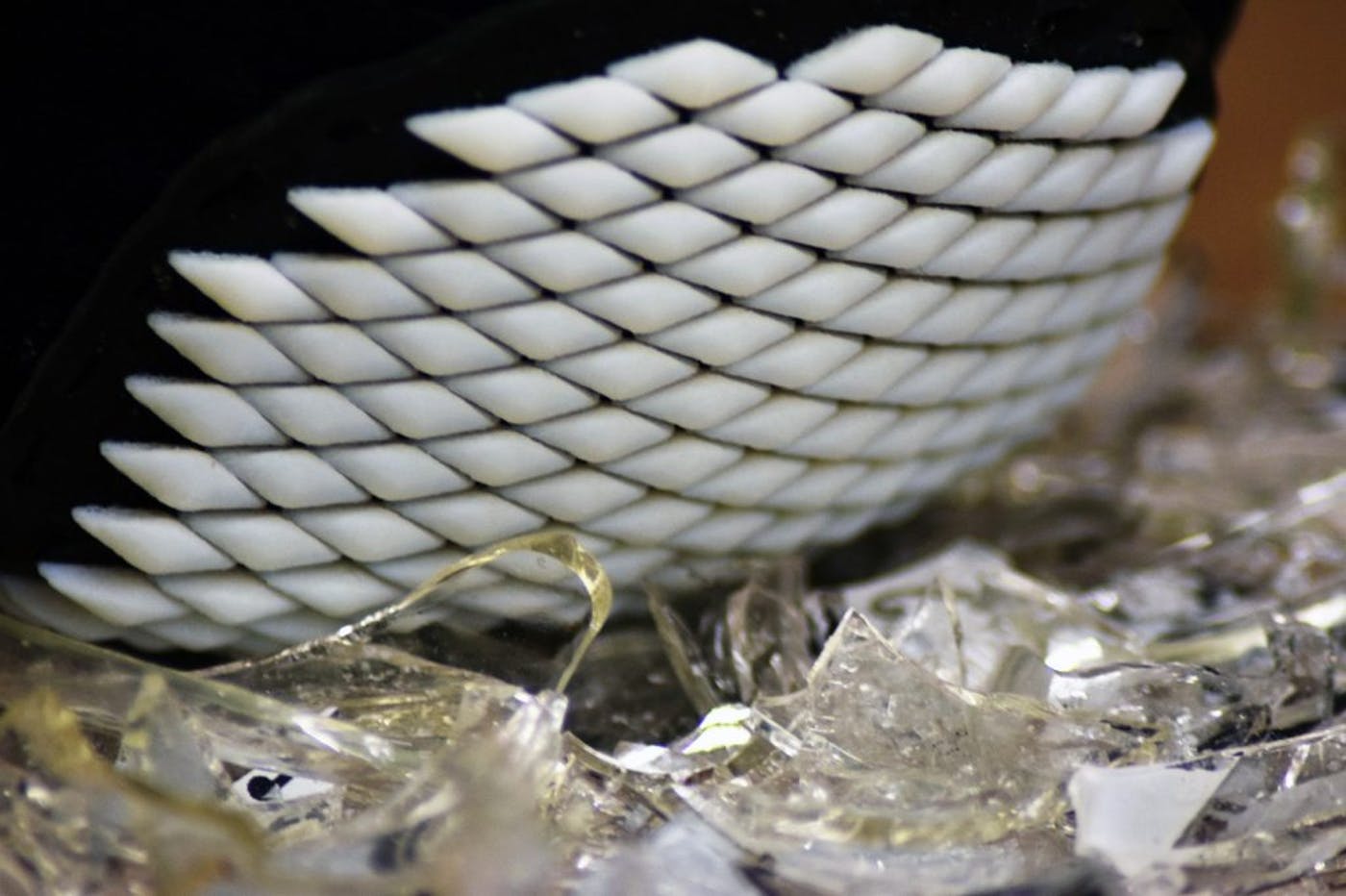

Elsewhere, 3D Printing Media Network reports from boot Dusseldorf, where JAMADE Germany has just recently announced AMAZEA, the first serially 3D printed underwater scooter.

JAMADE Germany, which is “a company focused on the development and production of electrically powered sports equipment, developed and serially produced the AMAZEA underwater scooter using large format extrusion 3D printing technology. This marks a significant new era for digital mass production, as the AMAZEA will feature impressive 75% 3D printed parts, which actually make the device impossible (or very difficult) to produce by any other manufacturing method.”

AMAZEA’s body and front parts are produced “on three BigRep ONE large-format 3D printers using engineering-grade materials. With the exception of the Olli autonomous vehicle, this is the first time an end-use product this large is produced largely by 3D printing. The greater availability and lower costs of both large-format 3D printers and durable 3D printable materials is going to continue to enable a new generation of digital products.”

JAMADE Founder and Managing Partner Janko Duch explains: “AMAZEA is an industry-first breakthrough with the potential to redefine maritime vehicle technology and the consumer experience in water sports around the world. We opted for the BigRep ONE due to its cost efficiency, accuracy, and quality when compared to the extremely high investment for traditional tools, particularly in the first year’s lower quantity.”

AMAZEA “pulls the diver attached to it forward through the water, is an environmentally friendly, emission-free, and low-noise method of exploring marine life without disrupting the eco-system.”

In the design world, Dezeen reports on yet another pavilion getting 3D printed in Saudi Arabia. Only this time, it was created using sand.

This “sustainable sand-printed installation called Sandwaves” is located in Diryah, Saudi Arabia specifically and was created by architects Chris Precht and Arthur Mamou-Mani.

“The ribbon-like structure is 3D printed from sand and furan resin for use as street furniture at Diryah Season – a sports and entertainment event in the Al-Turaif District.”

The architects chose sand due to the fact “it is the most abundant natural material in the country, and it also responds to local building traditions.” With this 3D printed art installation, the pair of architects “hope to demonstrate the kind of innovation needed for our time in the building industry, and how nature and technology can work harmoniously together.”

As Mamou-Mani elaborates: “we both believe in the cradle-to-cradle approach to design, using materials which can go back to their natural state, leaving no trace.” To Precht, “building in an ecological way also means to build with local materials.” Mamou-Mani concludes: “we asked ourselves what is the most common raw material around, so sand came naturally to our minds.”

Sandwaves, which comprises “58 individual 3D printed elements which combine to form the continuous ribbon,” is the “largest sand-printed installation to date.” The architects collaborated with engineers at Format, “who used parametric design tools to generate the optimum shape and thickness of each piece.”

Finally, 3D Printing Industry reports Scan Dimension, a 3D scanner developer “with offices in the US and Denmark, has announced an update to the software for its SOL 3D scanner.”

With this update, Scan Dimension is providing “a number of new and improved features for the scanner, including improved scanning speed, and support for the latest macOS Catalina 10.15.”

Scan Dimension’s Head of Global Marketing, Global Scanning Rune Steenberg explains: “our engineers are continually advancing the SOL 3D scanner, and our customers will appreciate the faster scanning speed and support for macOS Catalina.”

“The latest update is making it easier than ever for SOL users to share, print, or save their projects for future use.”

Scan Dimension, a subsidiary of Global Scanning A/S, which is “a Danish manufacturer of scanning technologies. Global Scanning A/S primarily develops large-format scanning solutions for the computer-aided design (CAD), geographic information systems (GIS), reprographic products, copy services, and document archiving segments through its various companies,” is itself “a provider of 3D scanners, imaging, and realization technology, It provides its scanning solutions to customers in a number of industries, including construction, engineering, manufacturing, makers, and more.”

Scan Dimension introduced the SOL 3D scanner in April of 2019. “The system is designed to be easy to use and intuitive, intended for the everyday maker, technology enthusiast, and hobbyist.”

As Global Scanning A/S’s CEO Graham Tinn concludes: “we created the SOL scanner to make 3D scanning approachable for everyone. SOL empowers anyone to unleash their creativity and explore the infinite possibilities of 3D technology actualization.”

The 3D printed world keeps spinning…

Image Courtesy of Local 12 and BigRep

Quotes Courtesy of Local 12, BigRep, 3D Printing Media Network, Dezeen, and 3D Printing Industry